Assembly Line Cleaning

- CQC Compliance

- Medical Grade ATP Testing and ULV Fogging

- ISO Quality Care and Professionalism

- Competitive Pricing with Quick & Easy Quotes

- GBAC Star Accreditation

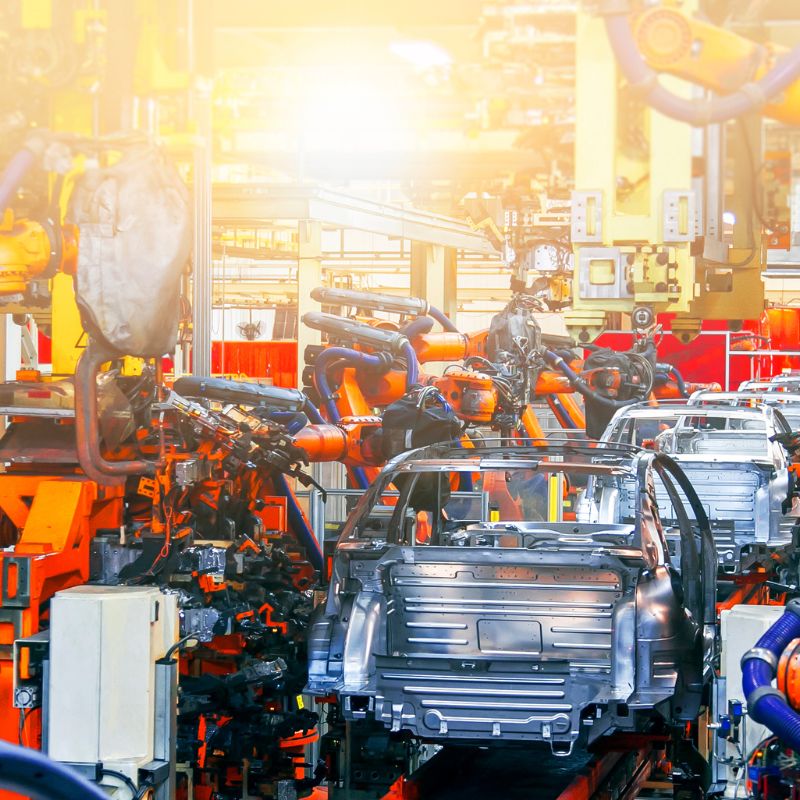

Assembly Line Cleaning

The term “assembly line” refers to a certain type of manufacturing process (also known as “progressive assembly”) in which a semi-completed assembly is passed from one workstation to the next, where individual components are added in turn until the final assembly is completed. A finished product can be assembled more quickly and with less effort by using machinery to transport parts to the assembly work and transport the partially assembled product from work station to work station.

We’re a leading industrial cleaning company with specialist skills in the cleaning of assembly lines. Regular cleaning and maintenance of assembly lines is critical. Over time, factory assembly machinery is exposed to grease, oil, dust, and pollutants. Failing to clean your manufacturing facilities may result in expensive and reputation-damaging effects. It can also lead to significant risks to health and safety, tainted goods, or insufficient working conditions.

Maintaining the cleanliness of your manufacturing lines requires time, effort, and frequent maintenance, but it is well worth the effort. CICS provides both once-off and ongoing cleaning services to keep your manufacturing plant clean and hygienic.

Manufacturers are under great pressure to run their businesses effectively while adhering to government and industry requirements.Germs can live on surfaces for long periods of time increasing the danger of cross-contamination on assembly and manufacturing lines.

If the assembly line is maintained clean, the risk of defects and breakdowns should be decreased, allowing production to continue uninterrupted. Make every attempt to include cleaning into the production line’s normal services. Your manufacturing line will be subjected to frequent tests as part of the maintenance service contract you have in place to guarantee that it is operating at peak efficiency. As part of this procedure, your factory’s maintenance engineer will be able to detect and report any possible concerns, including those connected to the factory’s degree of cleanliness. Having these contracts in place will benefit you by allowing you to continue producing in addition to your usual cleaning efforts.

Our Assembly Line Cleaning Service

We are fully compliant with ISSA, GBAC, and ISO 9001, 14001 & 45001 accreditation. We are also accredited members of the National Academy of Crime Scene cleaning (NACSC), and have several years of experience in cleaning contaminated commercial and public spaces. Our virus disinfection cleaning involves highly specialised techniques including ULV fogging technology and the use of ATP testing devices that are particularly suited to ambulances, police cars, and other emergency vehicles. We also have a highly qualified bio-hazard decontamination team that specialise in the cleanup of bio-hazards on industrial sites.

- Free Site Visits

- Experienced Cleaning Technicians

- ISO and ISSA Accredited

- Outstanding Service Quality With ISO 9001/14001/45001

- COSHH Compliance

- ULV Fogging Technology

- ISSA, PASMA and IPAF Accredited

- On-site Within 24 Hours

- Free Site Estimates and AdviceList Item